The South African rand gold mine is the world’s largest gold mine.The mine was discovered in 1866 and was soon put into production. So far, 130 years, has opened up to 35000 tons of gold, and now there are 18000 tons of reserves, still 52% of total world gold reserves.

In the process of gold mining, rock crusher is used for crushing gold into small pieces of gold production, andis also used in the mining of limestone, granite, coal mining, sand manufacturing plants, iron ore mining, etc. Rock crushing workshop production generally includes crushing, screening and possible washing. It may be necessary for separated into discrete fractions, re-combined and mixed. There are mobile rock crusher plant has more advantages, give you more convenient.Large cone crusher, jaw crusher is necessary in the gold mining process, so many manufacturers who produce the rock crusher.

Because of the deep underground mining, sulfide mineral type gold ore mining requirements have a higher ore grade, simple optional sulfide ore minimum industrial requirements in 2 g/T, the average grade of mining in 4g/ ton to profit.

From the primary simple sulfide gold concentrate, gold extraction generally have two methods, one is roasting – cyanide method, two is bio oxidation extraction method, the former requires a set of sealing performance is very good, because most of the gold concentrate containing arsenic, the arsenic containing waste water treatment, will seriously poison factory environment, the formation of acid rain is directly harmful to the ground, so it is very dangerous.

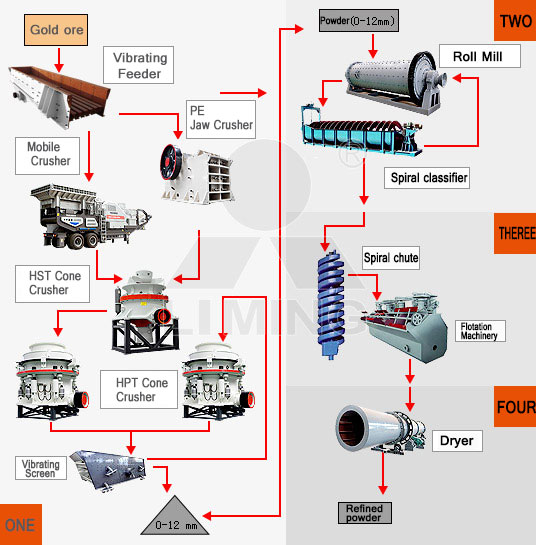

But in the modern gold ore crushing process, the three section is the best way, can complete the ore crushing and part of the work, so as to improve the efficiency of subsequent grinding.

During the grinding process, the two stage of a closed grinding is an efficient grinding technology, which can make the gold ore grinding more fully.

In the beneficiation process, because of the difference of the various types and properties of gold ore, the separation methods also have different, but generally used gravity separation, flotation separation, amalgamation, cyanide and now the resin in pulp method, carbon in pulp adsorption method, heap leaching process for the new extracting gold technology. For certain types of ore, often using combined gold extraction process.

Details are shown in Figure: