Road and Bridge Engineering Materials thousands of years ago began to use gypsum and limestone as a cementitious material, followed by the beginning of the use of natural cement rock (clay content of 20% -25% of lime) the calcination, finely ground to obtain a natural cement. In the 21st century, high-performance concrete as a structural material has been widely used.

Road bridge construction is generally divided into surface layer structure, primary structure, cushion structure and composition, which are inseparable from each layer of aggregate material. The strength of its pavement, hardness, stability, durability and so need to sand and gravel mix to decide. Especially cushion, need gravel sand or gravel mixture, binder to reduce the deformation of subgrade.

Roads and bridges railway construction sand concrete

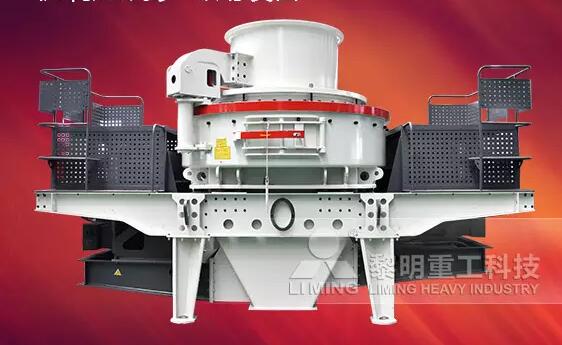

Gravel is the main material of concrete composition, with emphasis on the development of construction industry and construction quality of the construction market by increasing the number of sand, also known by the 5X sand making machine and stone shaping sand production line to build the building, its production of sand and gravel aggregate, grain shape is good, uniform particle size, which build concrete performance comparable to natural sand concrete.

Sand concrete high-end equipment –5X Sand

Feed range: 0-50mm Capacity: 70-640 t /

5X Sand crusher is sand and gravel aggregate production equipment manufacturing another breakthrough. It has a stone cosmetic effect, it can provide the best quality sand and gravel aggregate for the highway, railway, high-rise buildings, the construction of hydroelectric dams, ports, concrete mixing stations, has now become the aggregates production companies preferred sand equipment, widely used in river gravel sand, tailings sand, building sand and other fields …..

Outstanding advantages:

1, high-quality materials escort

The United States selected high-temperature wear-resistant materials to build the core components. Used in Japan, Sweden, the United States and other international brand bearings. Selection of high efficiency, low noise, high degree of protection motor.

2, minimize wear and tear parts

Next week fender adjustable, improve material utilization, improve the life of more than 48%. Combined hammer, simply replace worn hammer, reduce the cost by more than 30%. Diamond-shaped impact block, increasing the hammerhead, the damage probability of the lowest vertical plate.

3, the ability to increase throughput

Optimization deep cavity-type rotor design, the material throughput increased by about 30%. Smooth curve-shaped design and optimal emission mouth, reduce the flow resistance of the material, greatly improve the capacity of the material.

River gravel sand production line

Device: HST100S1 single cylinder hydraulic cone crusher, 5X1145 Sand crusher, 4YZS2460 shaker, XSD3016 sand washing machine

The material: river pebbles

Feed size: 0-240mm

Discharge size: 0-5mm

Production capacity: 120t / h

Applications: Concrete