Coal, as a high-quality fuel, is widely used in metallurgical, chemical, cement, electricity, heating, heating, boilers and other industries. At the same time, coal is a valuable non-renewable energy sources, the current large-scale thermal power plants with pulverized coal boiler still dominated in recent years with the growing scarcity of coal resources, coal processing and utilization are moving fine direction.

Liming Heavy Industry has a leading technology service team, including 25 senior engineers, 46 senior technicians 165 people, after years of hard exploration, the establishment of a complete and effective service system, the customer base for the planning and site survey in for our customers to provide detailed project design, equipment selection to provide the best solutions, equipment lists and project cost, basic site design drawings, and can design special technology and process according to the special requirements of customers.

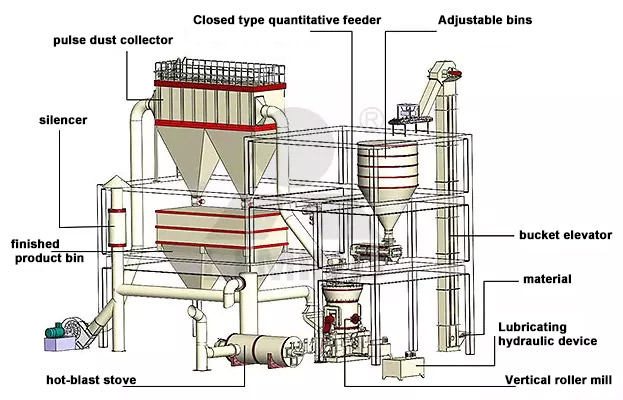

System Process Outlined

Coal from the coal yard grid mesh sieve after falling large angle belt conveyor or hoisting machine, the magnetic separator in addition to iron, the conveyor belt or hoist the coal into the coal bin for storage through.

After milling system has been started, open the valve rod bottom coal storage, metering start sealing tape to coal, raw coal into the coal vertical mill drying, grinding.

By the stove out of hot air or gas in the system fan evacuating down into vertical coal mill, and the mill was grinding coal sufficiently heat exchanged with pulverized coal from the sorting office in the separator, fine Pulverized of crude fell again failed were grinding on the disc, qualified pulverized coal into the air explosion-proof air box pulse dust collector is collected down through the sub-grid wheel unloading of coal warehouse.

Raw coal debris, as part of the gangue, piece of metal, etc., through the air ring, spit slag discharged out grinding.

Production process oxygen and carbon monoxide detection device, when high volatile coal processing, the system is provided with a nitrogen and carbon dioxide fire extinguishing system, safe and reliable.

Lime Kiln Coal Powder Preparatio

Calcined lime kiln to now, metallurgy, chemicals, building materials industries by increasing the amount of ash, especially in the steel industry, calcium carbide industry, alumina industry and refractory industry, lime quality requirements more higher and higher. The development of modern lime kiln demand for coal increasing, but also on the pulverized coal processing equipment put forward higher requirements.