AGGREGATE CRUSHER & PROCESSING

Aggregate Manufacturing typically starts by blasting rock masses and is followed by a series of crushing stages. Crushing operations can accommodate some adjustment to match the demand for each gradation. Aggregate is a broad category of coarse particulate material used in construction, including sand, gravel, crushed stone, slag, recycled concrete and geosynthetic aggregates. Aggregates are the most mined material in the world.

AGGREGATE CRUSHER & PROCESSING

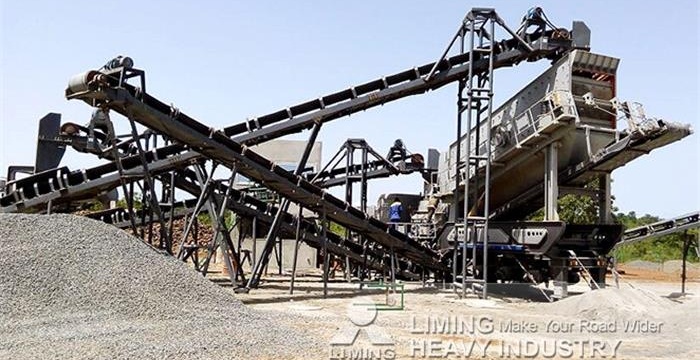

Liming Heavy Industry is a premier supplier of crushing and screening equipment, and related auxiliary equipment in China. We provide complete crushers and screen machines for producing all types of aggregate. The input capacity of One unit of aggregate production line up to 800-1000 TPH, the input size is 0-15mm.

Aggregate production line produce construction aggregates widely used for making concrete production. The aggregate process consists by progressive stages of crushing, screening, and washing.

The aggregate production flow:

1.The blasted raw stones was hauled to the a stockpile by heavy duty truck;

2.The raw stones like granite, basalt, marble, limestone, cobble stone etc. will be fed into jaw crusher as primary crushing machine;

3.The crushed stones will be transferred to impact crusher for further processing;

4.According to the clients application, the crushed stone will be sieved into different grade by vibrating screen, or be transferred to cone crusher for fineness crushing;

5.After screening process, aggregate washing machine will be needed to clear away the dust and small particles.