Cement is an important construction materials, cement mortar or concrete made, rugged durability, widely used in civil construction, water conservancy, national defense and other projects.

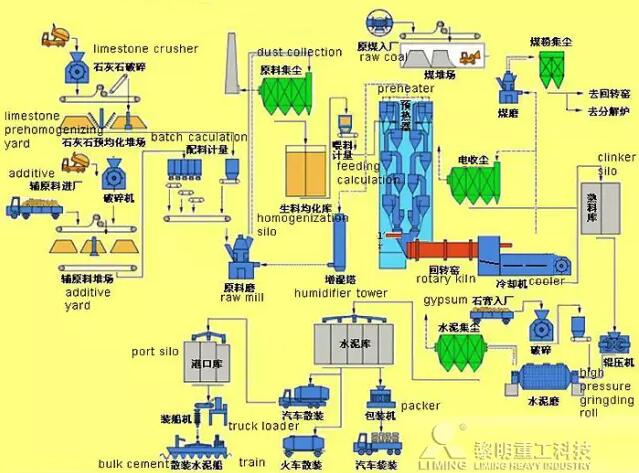

In the cement production process systems, mainly after grinding the raw material made of crushed raw material, in turn fed to the high-temperature furnace with its fuel burning mature, and finally the clinker is mixed with an appropriate amount of gypsum into cement grinding . The whole process can be summarized as mining, raw material crushing, drying clay, raw material grinding, coal preparation, clinker, clinker cooling, cement grinding and packaging products, and other procedures.

In the cement production process systems, mainly after grinding the raw material made of crushed raw material, in turn fed to the high-temperature furnace with its fuel burning mature, and finally the clinker is mixed with an appropriate amount of gypsum into cement grinding . The whole process can be summarized as mining, raw material crushing, drying clay, raw material grinding, coal preparation, clinker, clinker cooling, cement grinding and packaging products, and other procedures.

In the cement production process, coal

preparation is an important part. After the cement burning coal required, subject to crushing grinding, made to meet the requirements of burning pulverized coal particle size, respectively, to the kiln and kiln decomposing furnace, in order to fully burn, sufficient combustion reaction capability. Among them, the influence of the fineness of pulverized coal firing in turn affects the quality of the cement clinker, therefore, choose a machine that can improve the efficiency of coal mill and coal fineness of mill for cement production enterprises is very important.

Coal from the coal yard grid mesh sieve after falling large angle belt conveyor or hoisting machine, the magnetic separator in addition to iron, the conveyor belt or hoist the coal into the coal bin for storage through. After milling system to be started, open the valve rod bottom coal storage, metering start sealing tape coal feeder, coal into the mill drying, grinding. By the stove out of hot air or gas in the system fan evacuating down into the mill, and the mill was grinding coal sufficiently heat exchanged with pulverized coal from the sorting office in the separator, fineness unqualified coarse pulverized coal were brought back to the grinding disc on qualified pulverized coal into the air explosion-proof air box pulse dust collector is collected down through the sub-grid wheel unloading of coal warehouse.