Gypsum powder production line is a natural mineral gypsum (gypsum) or industrial by-product gypsum (gypsum, phosphogypsum, etc.) After a certain heating temperature calcining and grinding to make gypsum dehydration decomposition, resulting in β hemihydrate gypsum ( CaSO4 • 1 / 2H2O) as the main component of the product, that is, building gypsum (through the plaster).

Liming Heavy Industry Science and Technology for gypsum many other features, developed a high-yield and efficient gypsum powder production techniques. The technology for the production of dry, since the mill managed to achieve, through the frequency efficiency classifiers can be directly ground gypsum to conform “Gypsum” GB / T9776-2008 standard, no longer need to go through an external screening or sorting. And because the internal air circulation, can quickly meet the finished gypsum powder blowing elected to completely avoid over-grinding phenomenon, greatly improving the yield and productivity; at the same time thanks to the advanced ESP system meet the national environmental protection requirements.

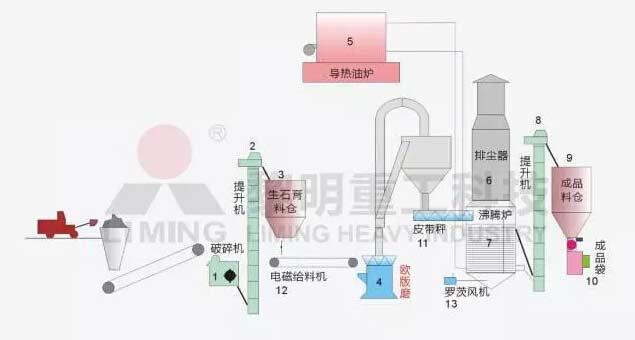

Crusher large gypsum ore broken into small particles less than 30mm, and transported to the mill grinding, the separator after grinding to achieve the desired product fineness powder into raw gypsum boiling furnace to calcine the rest partial returns mill grinding until qualified again. Calcined gypsum powder into the clinker qualified memory or storage products into the workshop.

According to process requirements, gypsum powder production line is usually divided into five parts, namely crushing system, grinding system, firing system, storage conveying systems and electronic control systems.

Crushing System

The main raw materials to complete the broken plaster block consists of jaw crusher for primary crushing, homogenization in the discharge field partition layout, and then by the secondary crushing cone crusher (or crusher) to 30mm of small particles into the silo.

Conveyor system

After breaking through the gypsum material conveyed to the storage silo elevator spare.

Grinding System

Storage bin in the electromagnetic vibrating feeder evenly gypsum raw materials are continuously fed into the mill for grinding. After grinding gypsum flour mill by the blower airflow blown bulging, after analysis machine at the top of the classification. Fineness meet the specifications of the powder, with the airflow into the large cyclone collector, collected through a powder discharge pipe is 80 to 120 mesh products.

Calcining system

Transport system over from grinding flour, transported to the boiling furnace firing, firing after a good meal cooked by the lifting conveyor to the finished product warehouse spare.

Electronic Control System

Electrical control system uses current advanced centralized control, DCS control or PLC control, all control elements are made internationally famous brand products.