VU is a leading global systems of aggregate dry sand system. It broke the limitations of traditional sand process to produce the VU sand comparable to natural sand, sand production mechanism to solve quality problems and create new opportunities and value for gravel, cement, concrete industry chain development.

VU is a leading global systems of aggregate dry sand system. It broke the limitations of traditional sand process to produce the VU sand comparable to natural sand, sand production mechanism to solve quality problems and create new opportunities and value for gravel, cement, concrete industry chain development.

VU Aggregates system uses a fully enclosed tower arrangement, workmanship maximize the reproduction of natural sand formation process naturally broken, the role of friction, washing, and thus in the finished sand grain shape, size distribution, the amount of powder containing other indicators has greatly improved performance can be comparable to natural sand. Moreover, because it is fully enclosed structure, the system control in the powder, there is also praiseworthy, no dust can achieve on-site, green.

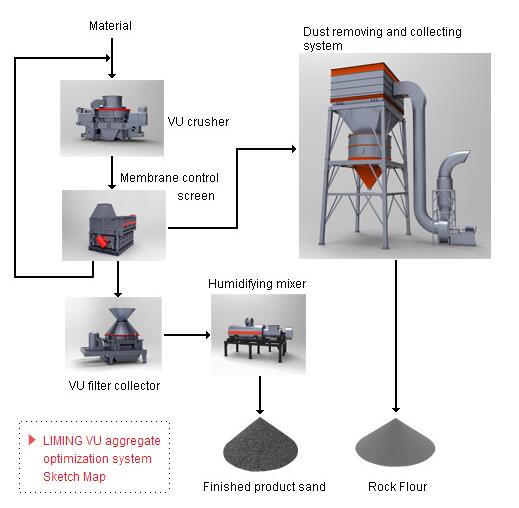

VU entire system consists of aggregate impact broke VU, VU excellent grain, dust removal and dust collection systems, analog control screen, wetting mixer composition, is a comprehensive update and upgrade the original system of dry sand on set efficient sand, grain shape optimization, control powder, gradation adjustment, moisture control, environmental treatment in one. Raw materials less than 15mm, even stone chips, melon rice stone such cheap and readily available raw materials, processed VU system, but also can produce with the management, rounded grain type, powder containing a controlled amount of finished sand. Of course, also includes a dry and clean, recycled powder can be unified.

VU Aggregates aggregate system to solve the traditional problems of preparation, will enhance the quality of sand to a new level, to meet the huge market demand for high-quality sand. For investors, it can undoubtedly bring generous returns.

High-quality finished sand

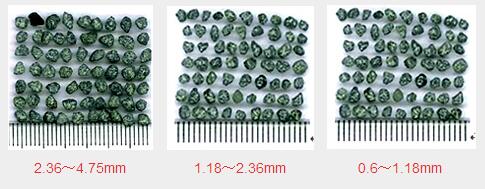

Finished sand grading, grain type, the amount of powder containing other process indicators is superior and stable performance, adjustable, with comparable quality natural sand.

Low consumption at low cost

Crushing and Grinding comprehensive technology innovation, reasonable convergence of single equipment performance and process improvement, to achieve a low consumption; use “Chips,” “melon seeds” and other cheap tailings, waste sand as the raw material to achieve a low cost.

Adjustable fineness modulus

Convenience (2.2-3.2) fineness modulus adjustment.

More precise classification

Classification precision is much better than before, by adding water and wet sand mixer may produce the same product.

Environmental Technology

Equipment fully enclosed structure, dust does not spill. Environmentally friendly dry process, no water, no sewage, sludge, dust and other issues.

Has a natural sand savior –VU of aggregate system, high-quality sand is no longer a difficult task!