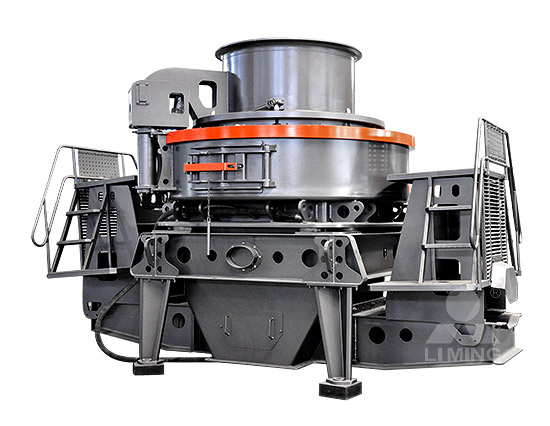

VSI6X vertical shaft impact crusher is absorbing many years of experience and technology concepts, with a new four wheel structure design and special sealing structure to prevent oil spills and other bearing cartridge technology, with a number of national patents of new high efficiency sand crushing equipment with energy efficient, long service life, widely used and so on.

Applications: metallic and non-metallic minerals, building materials, artificial sand, metallurgical slag

The material: river gravel, granite, basalt, iron ore, limestone, calcite, quartz, diabase, coal, calcium carbide, etc.

Working Principle

Motor driven spindle bearing cartridge drive part for the high-speed rotation, and with the rotor shaft for high-speed rotation, the material is injected into the interior of the impeller impeller speed up to the crushing chamber, the material crushing cavity lining material formed collide with each other, compare notes, the material get broken or kinetic energy into shaping the material energy requirements, cycle times in the crushing cavity of the material under the effect of ambient gas vortex after many broken plastic in order to achieve continuous broken plastic material discharged from the lower portion of the body formed by the accelerated required finished material, the crushing mode is “stone at stone”, the model is mainly used in stone shaping broken; in addition the device is also equipped with a “stone blacksmith” broken way, with stone at different stone are: material from the rotor ejected after the crushing counterattack cavity block installation is hit, the material is accelerated to obtain energy into collision with the counterattack crusher block the energy required, after the impact of material discharged from the lower part of the body, can not be achieved in multiple cycles of crushing chamber broken, broken this way mainly applied to break the main (for the purpose of providing a large reduction ratio) in the workplace.

Technical Parameters

| Model | VSI6X1263 | |||

| Normal | Shaping | |||

| Yield(t/h) | 454-486 | 547-586 | ||

| Max feed size(mm) | 50 | 60 | ||

| Speed(r/min) | 1200~860 | |||

| Double motor power(kW) | 630 | |||

| Maximum dimensions Length × width × height(mm) |

5700X2980X4190 | |||

| Weight(t) | Stone and stone | 20 | ||

| Stone and iron | 23 | |||

| Mains | Voltage(V):AC380、480、440、415、400 Frequency(Hz):50、60 |

|||

| Oil lubrication station | Flow(L/min) | 20 | ||

| Motor Power(kW) | 0.75 | |||

| Safety Protection | No oil flow automatically shut down; air-cooled; winter heating system startup. | |||

| Heater power(kW) | 4 | |||