Advantages of pulverized coal boiler equipment:

1. Reducing energy consumption and pollutant emissions:

The conventional pulverized coal-fired boiler to burn pulverized coal boiler is higher than 98%, the boiler thermal efficiency higher than 90%, compared with 30% energy saving over traditional boiler soot ≤30mg / m3, sulfur dioxide ≤100mg / m3, nitrogen oxides ≤200mg / m3, lower than the national emission standards, to meet stringent environmental requirements throughout.

2. Improve economic efficiency:

Compared with traditional pulverized coal boiler coal-fired boiler, equipment and control part of the investment was essentially flat, but less than in the conventional pulverized coal boiler boiler land 60%, no grate, coal, slag and other ancillary equipment, can be automated operation, equipment maintenance and significantly reduce labor costs, integrated operating costs reduced by up to 20-30%; compared with gas-fired, pulverized coal boiler unit fuel procurement costs only about one-third of the calorific value gas boiler.

3. To promote the development of downstream industries:

Fly ash produced after coal combustion can be used to produce new building materials, and promote the development of building materials industry chain.

LM vertical mill coal preparation process

By feeding coal into the coal belt conveyor warehouse for storage, enclosed by quantitative feeder feeds the coal inside LM vertical mill, hot air from the hot air into the system LM vertical mill inside, and coal mixing drying, enters the grinding chamber by a roller tray coal grinding and dynamic and static separator powder classifying, along a pipe into the coal mill dedicated dust collector pulse powder explosion collect, aggregate collection of finished pulverized coal by screw conveyor into the finished product coal warehouse for storage (also by pneumatic conveying, etc.), as needed transported by tankers. The entire system has a nitrogen system and carbon dioxide fire extinguishing system, providing explosion and fire protection, the key components are mounted explosion-proof valve.

Preparation of Pulverized Coal Mill MTW European version

Coal within the coal storage, transport equipment by entering the drying equipment for drying (optional on demand), by lifting machines and other equipment into the former mill surge bin, after drying coal via closed-quantitative feeder (or vibration feeder) after the coal feed MTW European version of the mill inside, powder separator after grinding through classification, along the pipeline into the powder collector (or coal mill special explosion-proof pulse dust collection, the collection of finished pulverized coal by pneumatic conveying system into the finished coal warehouse for storage (optional pneumatic conveying mode), as required by the tanker transport. The entire system can increase nitrogen system and carbon dioxide systems, providing explosion and fire protection, the key components are mounted explosion-proof valve, prevent equipment damage.

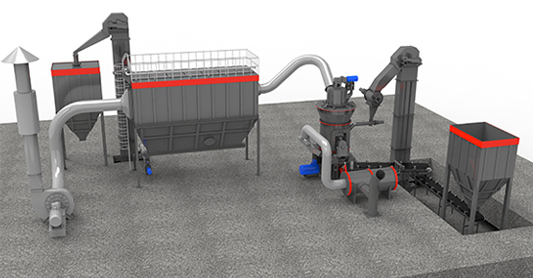

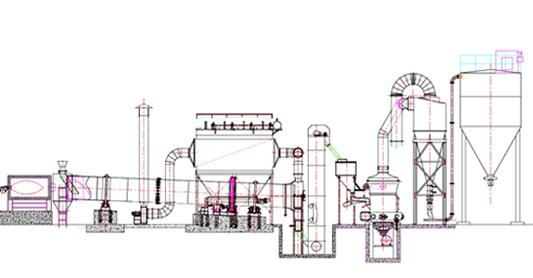

MTW European version of the mill three-dimensional flow chart

MTW Series European version of the mill complete system, a new generation of milling equipment with the world advanced level. The device uses a bevel gear overall drive, internal lubrication system, oil and many other online measurement world advanced technology, with a number of independent patent property rights, has a small footprint, low overall investment, low operating costs, high efficiency, environmental protection and many other advantages. System components: raw materials warehouse, closed dosing machine (optional), MTW European version of the mill, powder collector (coal mill dust explosion), fan, separator, drying systems, conveyor systems and so on.

MTW European version of the mill three-dimensional flow chart

MTW Series European version of the mill complete system, a new generation of milling equipment with the world advanced level. The device uses a bevel gear overall drive, internal lubrication system, oil and many other online measurement world advanced technology, with a number of independent patent property rights, has a small footprint, low overall investment, low operating costs, high efficiency, environmental protection and many other advantages. System components: raw materials warehouse, closed dosing machine (optional), MTW European version of the mill, powder collector (coal mill dust explosion), fan, separator, drying systems, conveyor systems and so on.