Large coal mining industry, coal-fired power plant construction, expansion or renovation, desulfurization technology has been widely applied, limestone – gypsum wet FGD technology is the most mature and efficient desulfurization process.

Limestone – gypsum wet FGD technology and what principle is it?

Out of the flue gas from the electrostatic precipitator through the fan into the heat exchanger, flue gas is cooled, into the absorber is mixed with limestone slurry. Some of the water in the slurry to evaporate, the flue gas is further cooled. Washed limestone slurry flue gas recirculation, flue gas can be more than 95% of the sulfur removal. While the flue gas of hydrogen chloride out. At the top of the absorber, the flue gas passes through demister to remove suspended water droplets.

Limestone – gypsum slurry is pumped into the settling tank from the absorber is mounted on top of the nozzle header column in the limestone – gypsum slurry spray tower along the process of falling in contact with the rising smoke it. SO2 in the flue gas dissolved in water, and is one of the basic substance, so that the flue gas sulfur removal. Calcium carbonate in limestone and sulfur dioxide and oxygen (oxygen in the air) react, and eventually to form gypsum, these gypsum precipitate out of solution in the tank. Gypsum slurry withdrawn from the absorption tower sedimentation tank, after concentration, dehydration and washing first store, and then transported away from the area.

In the desulfurization process, limestone flour milling equipment is mainly what machine?

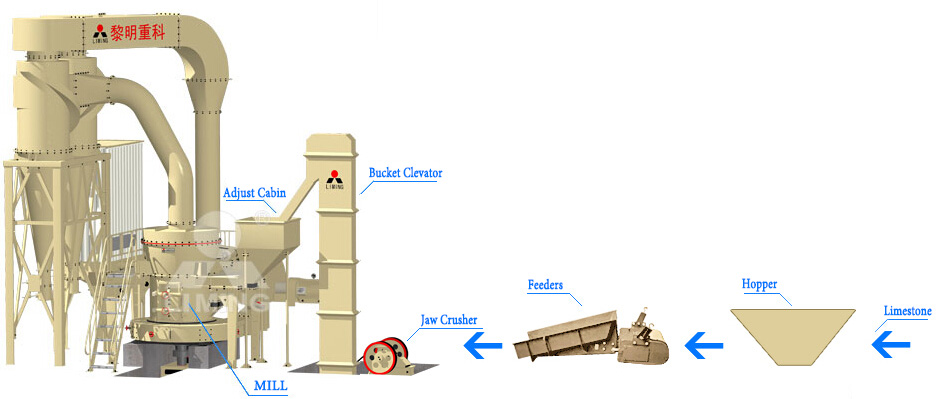

Desulfurization with limestone powder is generally about 325 mesh, Liming Heavy milling system for a thermal power plant desulfurization launched a total solution, and launched the European version of the latest upgrade –MTW Raymond mill, the raw material from the pre-test to post- installation, commissioning and acceptance, Dawn Heavy Industries to provide full guidance and main and auxiliary production testing equipment, and professional technical service team for your post-system maintenance.